Hyster Forklift Part - Hyster is globally renowned as an industry leader in the lift truck producing business. However, it began as a producer of lifting equipment and winches. Most of its production was focused in the Pacific Northwest and dealt mostly with the lumber and logging industry. A couple years after the first forklift trucks were invented Hyster became synonymous with quality production. Over the preceding eighty years Hyster has continued to get bigger and increase its product line. The expansion of its products coupled with its desire to stay service oriented has allowed Hyster to grow into the intercontinental participant it is in our day.

In the period between 1940 and 1960, Hyster continued its growth throughout the western world. In 1946, Hyster opened a plant in Danville, Illinois that was entirely committed to mass producing trucks. This allowed Hyster to drive its costs down and, at the same time, offer a better quality product at industry aggressive rates. In 1952, Hyster began its first foray in to the international production market through opening its first plant in the Netherlands. The Netherlands plant was originally designed to produce two products: Hyster 40" and the Karry Kranes.

The ever changing needs of Hyster clients and Hyster's skill to continue to innovate led to rapid expansion throughout the fifties and 60's. They began constructing container handlers in the United states in 1959 to satisfy the ever expanding demand for transportation goods. In 1966, Hyster developed a process for enabling a lift truck to go both ahead and backwards using the same pedal. This pedal was labeled the Monotrol pedal, which revolutionized the industry. Later on in the decade Hyster opened a research and development centre in Oregon that was focused on improving the design and performance of forklifts. The centre is still one of the world's greatest testing facilities in the materials handling industry.

The sixties was characterized by rapid growth right through the whole materials handling industry. Due to this, Hyster needed to refocus its strategy towards these growing mass markets. As a consequence, in 1970, the XL design philosophy was born. The XL design philosophy allowed Hyster to supply better quality at a more reasonable cost. A further expansion in production capabilities was necessitated by the demand in Europe for Internal Combustion Engine Vehicles. To plug this hole, a plant in Craigavon, Ireland was opened in 1980. Through the 80's Hyster continued to focus on developing industry leading forklifts. The Hyster company name was known throughout the globe for its dedication towards quality. This attention to excellence brought numerous suitors for the business. In 1989, a large international company based in Ohio called NACCO Industries bought Hyster and started an aggressive growth plan. NACCO promptly replaced the XL philosophy with a more driver oriented lift truck that focused on operator comfort, which is well-known as the XM generation of trucks.

The shift in supply change management to a much more just-in-time focused method has meant that Hyster has had to constantly invest in new technology. Acquisitions and investments were made in the US, Italy, Netherlands, and a lot of other places throughout the world. All of these investments have made Hyster a world leader in the forklift market. Recently, Hyster celebrated its eightieth anniversary as an industry leader of materials handling equipment, which includes over 300 various types of lift trucks.

![]() Click to Download the pdf

Click to Download the pdf

Forklift Parts

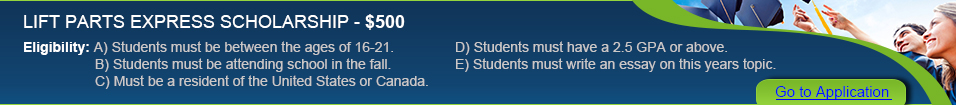

Lift Parts Express

TOLL FREE: 1-888-695-7994

forkliftpartsmaine.com

Email Us

About Us